|

|

|

ADVANCED INTEGRATED WASTEWATER POND SYSTEMS (AIWPS) By Tuba Ertas and Victor M. Ponce

|

| Abstract: Waste Stabilization Pond Systems are summarized and Advanced Integrated Wastewater Pond Systems (AIWPS) are investigated. Detailed study about each treatment units and reaction mechanisms are studied. Fecal coliform bacteria removal mechanisms, the effect of parameters such as temperature, pH, dissolved oxygen, organic loading, solar radiation on removal efficiency is investigated. Some of AIWPS applications are given, emphasizing removal efficiencies in every unit. Based on operational simplicity, low cost and high removal efficiencies (99% BOD5, suspended solids and coliform bacteria removal), AIWPS is highly recommended for up to 1000 mg/L BOD5 concentration. Because of its high coliform bacteria removal efficiency, the effluent of AIWPS may be used for irrigation purposes. |

|

Introduction

Waste Stabilization Ponds (WSP) are regarded as the method of first choice for the treatment of wastewater in many part of the world, because of design, construction and operation simplicity, cost effectiveness, low maintenance and energy requirements, easily adaptive for upgrading and high efficiency. WSP's are designed to achieve different forms of treatment in up to three stages in series, depending on the organic strength of the input waste and effluent quality objectives. Usually, classical WSP's consist of an anaerobic pond, following primary or secondary facultative ponds. If further pathogen reduction is necessary, maturation ponds will be introduced to provide tertiary treatment. Many techniques have been developed to improve the effluent quality. These are

Advanced integrated wastewater pond systems (AIWPS) AIWPS has been developed by Professor William J. Oswald and his co-workers at the University of California, Berkeley over the past four decades. Advanced Integrated Wastewater Pond Systems (AIWPS) are potentially feasible for application in the developing world [1]. Although AIWPS may appear to be an adapted traditional pond system, each AIWPS facility designs and incorporates a series of low-cost ponds or earthwork reactors. A typical AIWPS facility consists of a minimum of four ponds in series. These are Advanced Facultative Ponds (AFP), Secondary Facultative Ponds or Algal High Rate Ponds (HRP), Algae Settling Ponds (ASP), Maturation Ponds [2]. AIWPS's do not require sludge management; indeed the time in which sludge residues accumulate to require removal and disposal is on the order of decades. Carbon is transformed in AIWPS's through two important mechanisms: methane fermentation and biological assimilation by microalgae. The conversion of waste organic solids to methane, nitrogen gas and carbon dioxide via methane fermentation and the assimilation of organic and inorganic carbon to algal biomass via photosynthesis provide the basis for primary, secondary, and tertiary treatment in AIWPS's [2]. 1. Advanced facultative ponds The first of the four pond series is the Advanced Facultative Pond (AFP). The term facultative implies that waters in the pond are aerobic (oxic) near the surface and anaerobic (anoxic) near the bottom. Methane fermentation is the principal mechanism for BOD removal in AFP's. Conventionally designed waste stabilization ponds and other wastewater treatment processes tend to integrate carbon and generate large volume of sludges and, therefore, cause additional cost. However, AIWPS require much less capital, energy, operation and maintenance than mechanical systems and require less land, produce less odor, and fill in or age much more slowly than ordinary ponds [2]. In AFP's sedimentation and methane fermentation occur in deep pits specially designed to avoid the intrusion of dissolved oxygen. Raw waste is introduced near the bottom of these pits and, since they are deep and are loaded with upflow velocities, most of the settleable solids remain within the pits. Overflow velocities are designed to be low enough (less than 2.5 m/day) to allow most helminth (parasitic worms) ova to settle in the pit. Solids are lifted by the gas bubbles that form on and in them; but, as they rise, the bubbles expand and break away leaving the solids to resettle. The result is that solids with their adhering bacteria rise and fall within the pits creating an anaerobic sludge blanket through which all of the wastewater must flow. To deal with flotables, AFPs are designed with down-wind concrete "beaches" or scum ramps where floatable trash can be cast up by the wind to dry. Since AFPs are constant in depth, bank erosion is best controlled with a paved water line. A well designed AFP in the sunbelt will remove from 60% to 800 of the influent BOD and virtually all of the original suspended solids. Depth is regulated in an AFP by the level of the invert of the outlet pipe. The inlet of this pipe should be located below the surface to avoid transfer of floatables into the secondary pond. Because sludge removal from the AFP may be required every 10 to 30 years, there should be two units in parallel [1-3]. 2. Secondary facultative ponds or algal high rate ponds (HRP) The secondary unit of a conventional wastewater pond system is typically another facultative pond. However, much greater treatment is attained if the second unit is an algal high rate pond (HRP). Although it is much shallower than a secondary facultative pond, HRP requires a much shorter retention time and produces much more oxygen. The cultivation of algae is uncontrolled in conventional waste stabilization ponds, but in AIWPS's the growth of microalgae is optimized in paddle-wheel mixed HRP's. The second mechanism by which carbon is transformed and exported in AIWPS's is biological assimilation by microalgae grown in the HRP's. HRP's are designed to promote the symbiosis between microalgae and aerobic bacteria, each utilizing the major metabolic products of the other. Microalgae grow profusely releasing oxygen from water by photosynthesis. This oxygen is immediately available to bacteria to oxidize most of the soluble and biodegradable BOD remaining from the facultative pond [1, 2]. Microalgae in the influent from a paddle-wheel-mixed HRP settle readily; from 50% to 80% of the algae will be removed by sedimentation in a settling pond whose hydraulic residence time is one or two days. The settled algae have a low respiration rate and will remain concentrated on the settling pond bottom for many months or even years without releasing significant amounts of nutrients. Ideally, however, the algae should be removed periodically and used to its highest fixed nutrient and protein value [3]. One of the unique contributions of algae grown in HRP's is their daily elevation of pH in the pond. A pH of 9.2 for 24 hours is known to provide a 100% kill of E. coli and presumably most pathogenic bacteria. It is not uncommon to reach pH levels of 9.5 or 10 in HRP's during the day and to provide as a result a high disinfection rate. On the other hand, continuous input of settled sewage and complete flow mixing tends to conceal such high rates of disinfection. Because they usually produce a surplus of dissolved oxygen (usually several times the applied BOD), some HRP effluent is used to overlay the primary AFP with warm oxygen-rich water to absorb any odors of reduced substances coming from the anaerobic bottom or fermentation pits. The recirculation of HRP effluent to the AFP also assures the presence of oxygen-producing algae in the surface waters of the AFP. Effluent from a HRP should be taken from the surface to transfer only the most oxygenated, highest pH water. Programmed withdrawal only during the day will enhance both disinfection and other pH related benefits attained in HRP's [1, 3]. 3. Algae settling pondsThe HRP should be followed by an Algae Settling Pond (ASP) or some other method of removing algae from the HRP effluent. Algae which settle tend to hibernate and thus do not immediately decompose or produce nuisance. If the water from the HRP is to be used for crop irrigation, algae need not be removed; settling and storage should be sufficient to achieve an MPN of 103/100 ml or less in compliance with the latest agricultural reuse guidelines recommended by the World Health Organization. Higher removals to an MPN of less than 2.2/100 ml and a turbidity standard of 2 NTU may require flotation and/or filtration to remove residual algae and enhance disinfection. UV disinfection of the effluent may be required to meet viral standards when specified [3]. Harvesting algae by natural sedimentation implies that at least two settling units in parallel must be provided to allow periodic decantation and removal of the settled algal concentrate. If they are heavily chlorinated they will die, settle and release BOD depleting the level of dissolved oxygen in the bottom strata of the receiving water. If AIWPS's are designed properly to avoid short circuiting and to enhance disinfection, chlorination should not be necessary [2, 5]. 4. Maturation ponds If the effluent from an AIWPS having passed through the AFP-HRP-ASP sequence is to be reused for agricultural or landscape irrigation where human contact is expected, storage for a minimum of 10 to 15 days in a deep maturation pond or storage reservoir will provide adequate die away of pathogenic bacteria of human origin. Maturation ponds will be occupied seasonally by wild fowl-ducks, coots, geese, gulls, and many others birds. The E.coli they contribute are innocuous but will add to the measured MPN. Discharge of such effluents to constructed wetlands may satisfy concerns regarding human health risks and improve habitat. The risks are actually minimal. Maturation pond effluents meet the bacteriological guidelines recommended by WHO for agricultural reuse [2-5]. Biochemical reactions in advanced facultative pond The biochemical reactions occur in the Advanced Facultative Pond is shown schematically as follows:

Photosynthesis: CO2 + H2O --> CH2O + O2 Aerobic oxidation: CH2O + O2 --> CO2 + H2O Organic acid formation: 2CH2O --> CH3COOH Methanogenesis: CH3COOH --> CH4 + CO2

CO2 + 4H2 --> CH4 + 2H2

Hetetrophic nitrification: Fixed N --> NO3-

denitrification: 2NO3- + 3CH2O --> N2 + 3CO2 + 3H2O

The pond algae and the pond hetetrophic bacteria depend on each other: The algae act as oxygen generators and the bacteria use this algal oxygen for BOD removal, and the bacterially-produced carbon dioxide is fixed by algae. Some oxygen and some carbon dioxide enter the pond through reactions [3].

Its surface from the atmosphere, but most of the oxygen comes from the algal photosynthesis and most of the carbon dioxide from bacterial metabolism. The algal genera and species that predominate in a pond appear to be a function of the surface organic loading the pond receives and, in general, at higher organic loadings species diversity decreases [6]. Thus facultative ponds have fewer algal genera than maturation ponds and flagellate genera tend to predominate, whereas in maturation ponds diversity is greater and nonflagellates frequently predominate [6].

Fecal coliform bacteria removal

The function of maturation ponds (1-1.5 m) is the destruction of faecal bacteria, particularly pathogenic members of the Enterobacteriaceae, and fecal viruses. Fecal coliform (FC) bacteria are commonly used as indicators of fecal bacterial pathogens. Fecal viruses are removed by adsorption on to settleable solids and subsequent sedimentation of the algae when they die. Fecal bacterial removal is largely due to the activities of the pond algae [7]. When the algae are photosynthesizing rapidly, their demand for CO2 outstrips, its supply from bacterial metabolism and this leads to carbonate and bicarbonate dissociation [8]:

CO3-2 + H2O --> 2OH- + CO2

The resulting CO2 is fixed by the algae and the hydroxyl ions accumulate to raise the pH, which is rapidly lethal to fecal bacteria [5,10]. High levels of dissolved oxygen (due to algal photosynthesis) and high visible light intensities, in the presence of dissolved humic substances are rapidly fatal to fecal bacteria [11]. A properly designed series of maturation ponds, that is also well operated and maintained can easily reduce FC levels to below 1000/100ml, which is the WHO (1989) [9] recommendation for unrestricted crop irrigation [7].

Influence of temperature, pH, dissolved oxygen, organic loading and pond geometry and configuration Temperature plays an important role in the activity of phototrophs and hetetrophs in wastewater ponds. It also significantly affects anaerobic waste degradation in the pond sediments. No methanogenic activity and subsequent reduction of sludge volume occurs at temperatures below 15oC. BOD loading varies from 2.2 g/m2.day in cold climates to 5.6 g/m2.day in warmer climates. During the colder months, the ponds go anaerobic because of the lack of solar radiation and, hence, photosynthesis [12].

Removal or inactivation of pathogens in oxidation ponds is controlled by a variety of factors among which are temperature, sunlight, pH, lytic action of bacteriophages, predation by macroorganisms, and attachment to settleable solids [12]. Parhad and Rao [9], in their research in India, observed that E. Coli were removed rapidly at pH above 9.3. Pearson et. al. [10], using buffer solution for the investigation of the pH effect on fecal coliform die-off, observed that pH above 9 was detrimental. Other research, such as that of Troussellier et. al. [13], suggests that pH influences removal rate even without reaching the critical values suggested by Parhod and Rao [9] and Pearson et. al. [10]. Mayo [14] shows that the fecal coliform mortality rate constant increases with increasing pH. However, the correlation was poor (R=0.27), suggesting that factors other than pH might have played a major role in fecal coliform removal.

Mayo [14] shows that dissolved oxygen concentration does not play any role in the survival or mortality of fecal coliforms. This is in agreement with the work by Pearson et. al. [10]. Pearson et. al. [10] also reported, the rate of die-off under laboratory conditions was independent of light, but die-off accelerated with increasing temperatures in the range of 10-30oC. Other research findings, such as that of Curtis et. al. [11], suggest that in the presence of humic substances, oxygen radicals such as singlet oxygen, hydrogen peroxide, and probably superoxide detrimental to bacteria will be produced in proportion to the oxygen concentration. Coliform die-off in ponds decreases with an increase in BOD5 and pond depth [11]. However, Mayo [14] reported that the fecal coliform mortality rate constant is not affected by the volumetric soluble BOD5 loading rate.

KT values for fecal coliforms, salmonella and rotavirus differed from one another in the same ponds and for different pond types. Other factors include aeration, antibacterial extracellular algal compounds, depletion of nutrients, sunlight intensity, and growth of algae [11, 15]. The possible reasons for the efficient removal of bacteria are the following

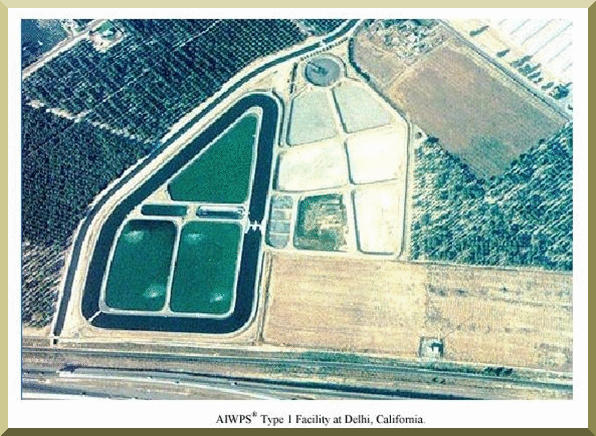

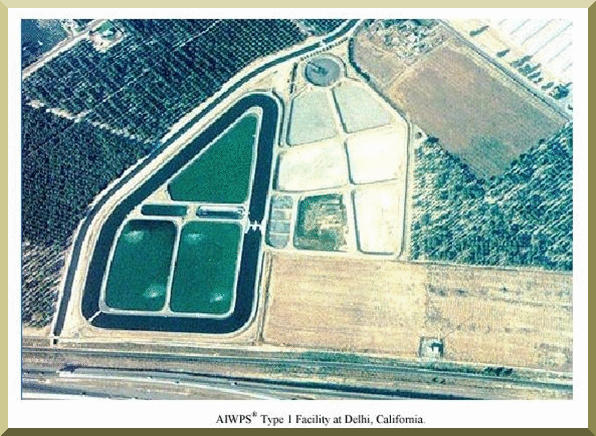

1. Long detention time used in oxidation ponds 2. High pH generated as a result of photosynthesis 3. Predation by zooplankton 4. Inactivating effect of sunlight. AIWPS applications The AIWPS in series of advanced facultative pond (AFP), secondary facultative pond (SFP) and maturation pond (MP) are studied for tannery wastewater by Tadesse et. al. [16]. Physical dimensions of the AIWPS reactors, and removal performances are summarized in Table 1 and 2. Water quality data shown in Table 3- 6 indicates the excellent treatment performance and superior effluent quality achieved by AIWPS prototype at Richmand, St. Helena, Hollister, Delhi [1-6].

The effluent ammonia-nitrogen concentration of the AFP was higher than its influent due to anaerobic ammonification of organic nitrogen in the lower fermentation pit. An increase in sulphate concentration in the final effluent could be due to the oxidation of sulphide back to sulphate in oxygen-rich shallow water column of the MP. The suspended solids from the two algal ponds (SFP and MP) also showed an increase in concentration and that was due to the production of more algal biomass [16]. Conclusion Based on the findings of this study, AIWPS are recommended as an efficient removal method for up to 1000 mg/L of BOD5 concentration. This method has been successfully operating for the last four decades in California. This treatment method has very important advantages such as very low energy and land requirements. Because of its high coliform bacteria removal efficieny, effluent of AIWPS may be used for irrigation purposes.

References

1. Oswald W. J. (1990). "Advanced Integrated Wastewater Pond Systems," ASCE Convention EE Div/ASCE, San Francisco,CA, Nov. 5-8, 1990.

2. Green F. B., Bernstone L., Lundquist T. J., Muir J., Tresan R. B., Oswald, W. J. (1995). "Methane Fermentation, Submerged Gas Collection, and The Fate of Carbon in Advanced Integrated Wastewater Pond Systems," Water Sci. Technol., 31 (12) 55-65.

3. Green F. B., Bernstone L., Lundquist T. J., Oswald, W. J. (1996). "Advanced Integrated Wastewater Pond Systems For Nitrogen Removal," Water Sci. Technol., 33 (7) 207-217.

4. Oswald W. J. (1995). "Ponds in the Twenty-First Century," Water Sci. Technol., 31 (12) 1-8.

5. Green F. B., Lunguist T. J., Oswald W. J. (1995). "Energetics of Advanced Integrated Wastewater Pond Systems," Water Sci. Tech., 31 (12) 9-20.

6. Pearson H. (2003). Handbook of Water and Wastewater Microbiology, Chapter 27, Microbial interactions in facultative and maturation ponds, Academic Press, UK.

7. Mara D. (2003). Handbook of Water and Wastewater Microbiology, Chapter 26, Low-cost treatment systems, Academic Press, UK.

8. Tadesse I., Green F. B., Puhakka J. A. (2004). "Seasonal and diurnal variations of temperature, pH and dissolved oxygen in advanced integrated wastewater pond system treating tannery effluent," Water Res., 38, pp. 645-654.

9. WHO Wastewater stabilization ponds: principles of planning and practice. WHO-EMRO Technical Publication No. 10. Alexandria, Egypt, 1987.

10. Pearson H. W., Mara D. D., Konig A., de Oliveira R., Mills S. W., Smallman D. J., Silva S. A. (1987). "Water column sampling as a rapid and efficient method of determining effluent quality and the performance of waste stabilization ponds," Water Sci. and Tech., 19 (12) 109-113.

11. Curtis T. P., Mara D. D., Silva S. A. (1992). "Influence of pH, Oxygen, and Humic Substances on Ability of Sunlight To Damage Fecal Coliforms in Waste Stabilization Pond Water," App. and Envir. Microb., 58 (4) 1335-1343.

12. Bitton G. (1994). Wastewater Microbiology, John Wiley & Sons, Inc., NY.

13. Trousselier M., Legendre P., Baleux B. (1986). "Modelling the evolution of bacterial densities in an eutrophic ecosystem (sewage lagoons)," Microbiol Ecology, 12 (4) 355-379.

14. Mayo A.W. (1992). "Faecal coliform and BOD reduction in facultative ponds under tropical climatic conditions," Proc. Int. Conf. On Envir. Protection and Control Technol., Envir. Mgmt. And Res. Association of Malaysia, Malaysia, Vol. 2, 477-488.

15. Pearson H. W., Mara D. D., Arridge H. A. (1995). "The influence of pond geometry and configuration on facultative and maturation waste stabilization pond performance and efficiency," Water Sci. Technol., 31 (12) 129-139.

16. Tadesse I., Green F. B., Puhakka J. A. (2004). "Seasonal and diurnal variations of temperature, pH and dissolved oxygen in advanced integrated wastewater pond system treating tannery effluent," Water Res., 38, 645-654.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||